How to Choose the Best Hydraulic Hose for Sale?

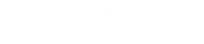

Choosing the right hydraulic hose for sale is crucial for any industrial application. The hydraulic hose market has shown significant growth, expected to reach $3.5 billion by 2025, according to industry reports. This demand reflects the increasing use of hydraulic systems in manufacturing and construction. However, not all hydraulic hoses are created equal, and selecting the right one can be a daunting task.

Quality and specifications matter greatly. A poorly chosen hose can lead to system failures, increased maintenance costs, and safety hazards. Evaluating factors like pressure rating, temperature tolerance, and oil compatibility is essential. Many businesses overlook these aspects, leading to costly mistakes. Moreover, with numerous suppliers in the market, finding reliable hydraulic hose for sale can be overwhelming.

It's also vital to consider the environment in which the hose will operate. Different applications demand specific materials and designs. For instance, a hose used in a high-temperature setting requires special attention. Failure to align hose selection with operational needs can bring about adverse outcomes. A thoughtful approach here can prevent headaches down the line.

Understanding Hydraulic Hose Specifications and Standards

When selecting a hydraulic hose, understanding specifications and standards is crucial. These components are not simply tubes. They carry fluids under pressure. A small mistake can lead to serious issues. Different applications require different specifications. Make sure to consider the working pressure of the hose. This is often measured in pounds per square inch (PSI).

Also, the temperature rating is important. Hoses are designed for various temperature ranges. Ignoring this can shorten their lifespan. Additionally, the hose’s material matters. Common materials include rubber, thermoplastic, and metal. Each has its strengths and weaknesses. Look closely at the environment the hose will operate in. Special factors like abrasion or chemical exposure come into play.

Standards ensure safety and reliability. Familiarize yourself with industry standards like SAE or ISO. These benchmarks illustrate quality and performance. However, not all hoses may meet these requirements perfectly. Quality control issues can arise, leading to subpar products. Inspect hoses carefully before purchase. Look for any signs of damage. Even minor defects can compromise functionality. Be prepared to ask questions and seek expert advice when needed.

How to Choose the Best Hydraulic Hose for Sale? - Understanding Hydraulic Hose Specifications and Standards

| Specification | Description | Typical Use | Pressure Rating (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| SAE 100R1 | Single wire braid reinforcement | General hydraulic applications | 3,000 | -40 to 212 |

| SAE 100R2 | Double wire braid reinforcement | High-pressure hydraulic systems | 4,000 | -40 to 212 |

| SAE 100R3 | Fiber braid reinforcement | Low pressure hydraulic systems | 2,000 | -40 to 212 |

| SAE 100R4 | Fiber or steel reinforcement | Return lines or suction | 1,200 | -40 to 212 |

| SAE 100R5 | Textile braid and spiral reinforcement | High-temperature and high-pressure applications | 3,000 | -40 to 212 |

Identifying the Right Hose Material Based on Application Needs

When selecting a hydraulic hose, the material is crucial. Different applications require tailored properties. Common materials include rubber, thermoplastic, and metal. Rubber hoses offer flexibility and durability. They are good for general use but may not withstand extreme temperatures. Thermoplastic hoses are lighter and resistant to many chemicals. However, they may not be as durable under high pressures.

Consider the application environment. For high-temperature conditions, a thermoplastic or metal hose may be advisable. For hydraulic systems, ensure the hose can handle the system pressure. According to industry reports, improper material selection can lead to hose failure in up to 30% of cases, causing costly downtime.

Tips: Always check pressure ratings and temperature limits. Look for hoses with certification labels. Be mindful of chemical compatibility. For frequent bends, choose a more flexible material. Match the hose construction to the intended application for better performance.

Evaluating Pressure Ratings and Working Conditions for Safety

When choosing a hydraulic hose, evaluating pressure ratings is crucial. The hose must withstand the maximum pressure it will encounter in operation. This requires understanding the specific working conditions. If a hose fails under pressure, it can lead to dangerous situations. Consider how high the pressure could be in real-world applications. A failure can cause injuries or equipment damage.

Working conditions also play a significant role in hose selection. Factors like temperature, vibration, and environmental exposure must be addressed. If a hose isn’t rated for extreme heat, it might degrade too quickly. Check for compatibility with various fluids as well. If the hose material breaks down, it compromises the entire system.

It's important to think about how the hose will be used daily. Pay attention to installation angles and bends. These can affect pressure ratings. Sometimes, we overlook small details that lead to bigger issues later. Regular inspections and thoughtful choices can prevent costly mistakes. Reflect on your choices often and adjust as needed for safety.

Assessing Hose Size and Fittings for Optimal Performance

When choosing a hydraulic hose, size and fittings matter. The wrong size can lead to leaks or inefficient performance. Measure the diameter carefully. A hose that is too narrow restricts flow. If it's too wide, you risk coupling issues.

Fittings also require attention. They must match the hose size well. If the fitting is incompatible, it can cause serious failures. Check the material of the fittings too. Some may corrode or weaken under pressure. It's essential to match these components properly.

Ignoring these details can lead to costly mistakes. A hose that does not fit perfectly may cause disruptions. Performance may suffer in heavy-duty applications. Always double-check your measurements and compatibility. This diligence can save time and money in the long run.

Comparing Manufacturers and Suppliers for Quality Assurance

When selecting a hydraulic hose, quality assurance is vital. Not all manufacturers and suppliers offer the same level of reliability. Begin by researching potential suppliers. Look for those with positive reviews and a strong track record. A well-established supplier often provides better support and service. Ask for recommendations from professionals in your industry.

Tips: Make a list of specific requirements for your hydraulic hose. This can include size, pressure ratings, and material. Compare this list against what suppliers offer. Don’t hesitate to reach out for clarifications. If a supplier is slow to respond or avoids questions, consider that a red flag.

Consider the manufacturing process. Inspect certifications and quality control measures. Are their products tested rigorously? Suppliers who invest in quality are often more trustworthy. However, be cautious about suppliers who can provide flashy marketing but lack real substance. Choose wisely and weigh your options carefully.